Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

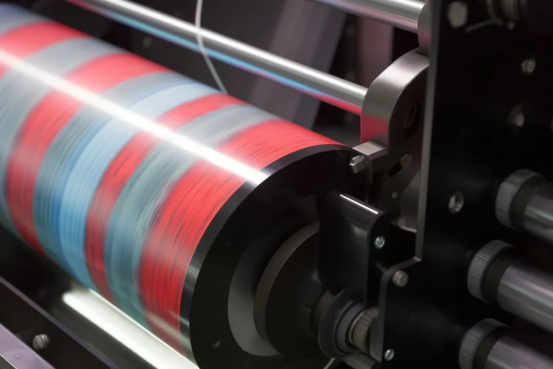

Solving Common "Puzzle Cases" with UV Inks

In the process of using UV inks, there are often some issues such as poor adhesion, stacking problems, and caking. These challenges are encountered by printing companies involved in labels. Siga would like to discuss these problems with the industry and their solutions.

Problems with Adhesion Issues and Solutions:

UV inks with insufficient curing can lead to poor adhesion of the printed ink layer on subsequent print items, resulting in stuck prints where the print material sticks to the backside of the printed item. This affects the quality of the print. To solve this problem of insufficient adhesion caused by poor cure, the most effective solution is to use UV inks with faster curing rates or UV inks with higher color concentration and thinner layers to achieve the desired color reproduction.

Problems with Stacking Issues and Solutions:

While stacking problems often involve issues such as insufficient adhesion, there are also specific solutions:

- Scheme One: Improve the surface properties of print materials by applying a transparent layer before printing. The UV inks will then adhere better due to the improved surface.

- Scheme Two: If improving the surface is not feasible during printing, a water-based primer can be applied to reduce caking and improve adhesion.

Analysis and Solutions for Stacking Problems:

Stacking issues are common when using UV inks. These stacking issues may also cause issues such as poor transfer quality and smearing of printed images. This occurs because the ink cannot flow properly through the printing plates due to insufficient flexibility, causing smearing. To address stacking problems during printing, adjusting the viscosity or applying a solvent can help improve flow.

Summary:

UV inks are commonly used by print companies for labels, but care must be taken when selecting and using them. Labels require different UV ink formulations based on the substrate they will adhere to. Printers who use UV ink should consider the performance of their substrates as well as the inks they choose.

When you encounter a problem with adhesion or stacking during printing, research the specific causes (whether it is caused by defective print media, caking, rough edges, insufficient adhesion layers, lack of adhesion to the substrate, insufficient flexibility, poor transfer, incomplete cure, inadequate surface tension properties, poor flow, or over-pigmented substrates) and adjust production parameters accordingly.